Digital strain measurement for wind turbines -

Optimizing the control & condition monitoring

Robust and stable strain sensor for sustained use.

The ESR strain sensor is based on an industrial sensor technology that has already been installed a million times over - optimally adapted to meet the high demands of wind turbines. The ESR x25 is designed to measure with zero force to prevent fatigue in the measuring section. The strain sensor features quick, easy and safe installation and can be adapted to the material of the surface to be measured. This allows the sensor to expand along with the material and, as a result, automatically provides passive temperature compensation.

DIGITAL ROBUST STRAIN SENSOR FOR LONG-TERM OPERATION

HIGH PRECISION

- Temperature compensation by adapted measurement arm

- Best in class sensor resolution 0.025 µɛ and measuring range ± 5000 µɛ

- Sampling frequency range up to 100 kHz

- Temperature check

- Sensor range reserve

- Plausibility checks

INTEGRATED DIAGNOSTICS

↵

- Protection Class IP64

- Lightning protection acc. IEC61400-24

- Stresslessmeasurement: fatigue-free

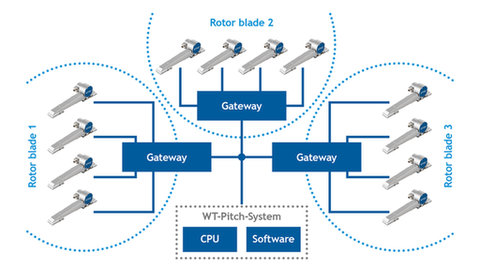

Rotor blade

- One to eight ESR x25 sensors per rotor blade

- Measurement direction along the rotor blade axis

- Several fieldbus gateways for sensor signal conversion

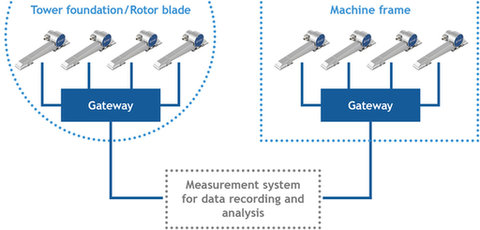

Machine frame

- Several ESR x25 sensors for strain measurement at the machine frame possible

- Several fieldbus gateways for sensor signal conversion

Tower and foundation

- Several ESR x25 sensors for strain measurement in the tower possible

- Measurement direction along longitudinal axis of the tower

- Several fieldbus gateways for sensor signal conversion

STRAIN MEASURMENT FOR …

CONTROL OPTIMIZATION

- Direct integration into wind turbine control system

- System components incl. strain sensors ESR x25 made for continuous operation

- Optionally provided software increases availability and reduces uncertainties

- Turbine control support for system calibration procedures

MEASUREMENT CAMPAIGNS

- Direct signal recording using data loggers

- Ideal for load measurement campaigns based on IEC 61400-13

- Installation 50% faster than conventional strain measurement systems

- Re-useable system components incl. strain sensors ESR x25

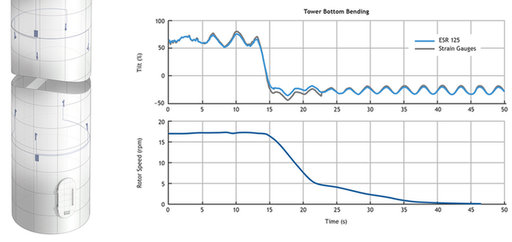

MEASUREMENT IN TOWER BOTTOM

- Comparison to strain gauge signals

- Good match between strain gauge and ESR

- No offset-drift at high deformation levels

- Better signal-to-noise ratio through larger measuring distance

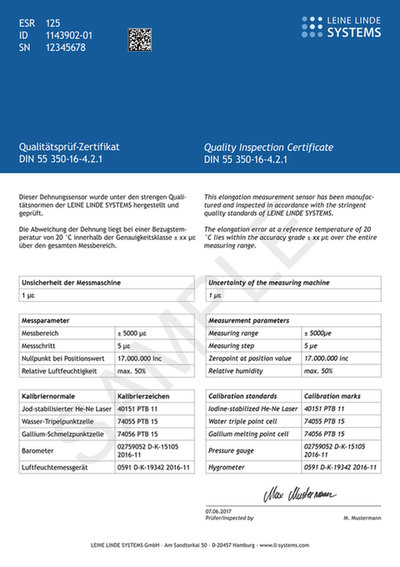

Measurement reports and certificates

- Every ESR sensor is tested for proper functioning and measured for precision

- Based on article and serial number a quality inspection certificate is supplied with each sensor

- Optional: On demand a DAkkS calibration according to DIN EN ISO/IEC 17025 can be performed