Feature

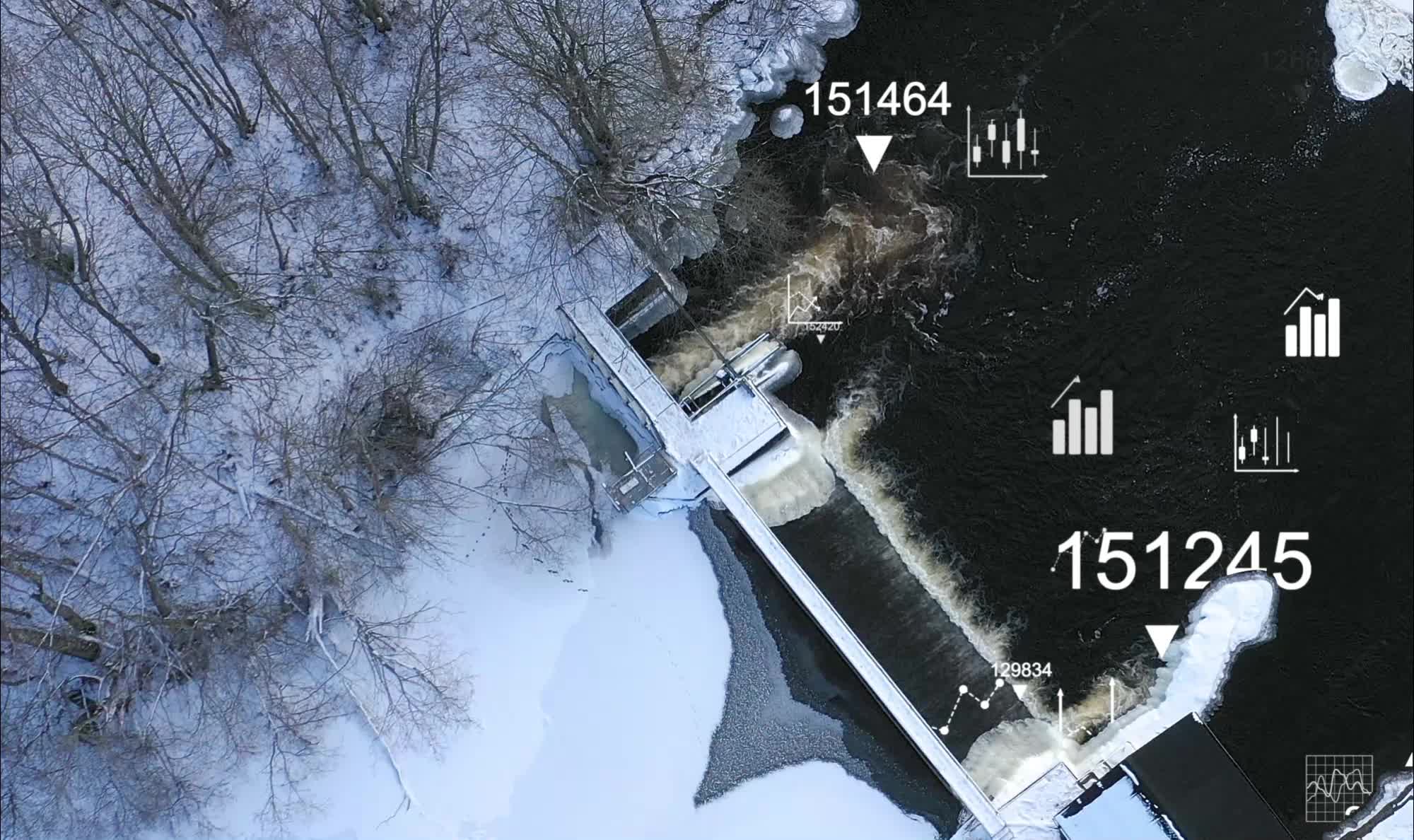

Winter hydropower operations in focus: from reactive to proactive management

As colder climates test the resilience of renewable infrastructure, Scarlett Evans explores how hydropower operators are refining ways to manage and monitor facilities in the winter.

Main video supplied by Peter Berglund/Creatas Video and by sedigheh shokranigheshlagh/Creatas Video+ / Getty Images Plus via Getty Images

Described by the International Energy Agency as the “forgotten giant of electricity”, hydropower is the mainstay of renewable energy, favoured for its flexible and robust nature.

Particularly crucial in providing grid flexibility for colder regions, hydropower generates almost as much as all other renewable technologies combined, and in 2024, the technology produced around 4,500 terawatt-hours of electricity – approximately 14% of the world’s total.

Yet despite its reputation for stability and longevity, hydropower faces an underestimated challenge: winter. For operators in cold climates, winter brings peak electricity demand alongside the most intense physical stress on infrastructure while water – the sector’s ‘fuel’ – becomes hardest to manage.

Warming winters are compounding this challenge, with shifting precipitation patterns, mid-winter thaws and accelerated snowmelt creating unpredictable conditions. In response, monitoring tools and predictive technologies are becoming increasingly integral to operations, helping shift sites from reactive to proactive strategies.

From remote sensing and advanced forecasting to specialised ice-management equipment, operators are deploying a growing range of tools to maintain reliability through even the harshest months.

A seasonal weak point

In winter, significantly less water flows through waterways as precipitation is locked up as snow and ice. At the same time, cold temperatures create river and frazil ice (crystalline ice that forms in supercooled, fast-moving water), as well as freeze–thaw cycles that disrupt intake flows, block spillways and increase mechanical wear on infrastructure.

International Hydropower Association vice-chair Dr Óli Sveinsson tells FuturePower Technology that ice issues alone can increase head losses (resistance to water flow), clog equipment and reduce available flow.

He comments: “Similar processes contribute to the formation of ice dams in river channels or in water diverted to open waterways that may be empty under normal operating conditions. These ice dams can cause water to impound and back up and be potentially diverted out of the main river course.”

Such issues can be particularly challenging for smaller, run-of-river facilities, triggering significant downstream flooding if an ice dam breaks suddenly.

Sveinsson adds that extreme weather can lead to difficulties in accessing hydropower facilities, with increasing weather volatility potentially exacerbating these vulnerabilities.

Despite the risks, hydropower sites are typically well designed to withstand temperature extremes, with cold weather considerations built into the general design of such facilities.

What has changed in recent years is the availability of data. Technologies such as remote sensing and satellite-based monitoring are providing operators with a new generation of tools to monitor everything from infrastructure status to weather, as well as forecast potential issues before they escalate.

New modalities have shown they can treat diseases that previously had poor standards of care.

Emmanuelle Cameau, Scientific Director of Viral Vectors at Cytiva

“New modalities have shown they can treat diseases that previously had poor standards of care,” said Emmanuelle Cameau, Scientific Director of Viral Vectors at Cytiva. Following their favourable results, drug developers are moving towards addressing more common diseases with these medicines.

“A significant factor is the continued shift toward more complex molecules, such as bispecific and trispecific antibodies or advanced fusion proteins,” Kasper Møller, Chief Technical Officer and General Manager of AGC Biologics’ Copenhagen Site, shared. Their increasing complexity requires greater investment in advanced analytical and process development capabilities to meet rising scientific and regulatory expectations.

“Now that cell and gene therapies have moved from hype to clinical reality, expansion into solid tumors and autoimmune diseases is dramatically increasing the number of patients who could benefit - if manufacturing could keep up,” said Fabian Gerlinghaus, Co-Founder and CEO at Cellares.

As biomanufacturing develops and manufacturers increasingly move from clinical trials to commercial production, pharmaceutical producers need more complex, and potentially larger manufacturing capabilities, to ensure they can produce scalable and compliant bioproduction platforms.

Digitising upstream: gathering more and better data

One of the most critical variables in managing hydropower’s winter operations is snow.

According to the European Space Agency (ESA), during the winter more than 50% of the water used for hydropower production in colder climates is stored as snow. Accurately measuring that storage is essential for managing flood risks, anticipating potential drought and forecasting power generation.

“In many parts of the world, hydropower essentially depends on snow,” says Sina Starmans, project manager at satellite data company EOMAP.

“Snow is where the water, and therefore the energy, is stored. Being able to calculate how much water is held in the snowpack is like knowing how much energy is still available up in the mountains.”

Snow is where the water, and therefore the energy, is stored. Being able to calculate how much water is held in the snowpack is like knowing how much energy is still available up in the mountains.

Fabian Gerlinghaus, Co-Founder and CEO at Cellares

Monitoring has traditionally relied on manual measurements and LiDAR mapping, which Starmans highlights as expensive, labour-intensive and infrequent. As a result, operators have historically been working with limited data.

EOMAP’s SnowPower technology pitches itself as a more cost-effective and accurate alternative. Integrating satellite and radar sensors from the ESA’s Sentinel-1 constellation, the system retrieves snow depth information across vast and often inaccessible areas, allowing operators to monitor snow water equivalent and melt dynamics.

Using this platform, EOMAP says operators can plan for sudden thaw events and schedule maintenance well in advance, with existing customers, including the Enel Group across its hydropower plants in the Alpine and Apennine regions.

“The more information operators have, the better they can manage their reservoirs,” Starmans adds.

“Better data helps them decide when to generate more or less power, anticipate excess water and ultimately maximise energy production from the available snow water equivalent.”

Crucially, such tools also provide operators with access to historical data, helping to identify long-term shifts in snowmelt patterns and inform future infrastructure planning.

Similar tools are seeing particular uptake across Europe. PowerEdge, an ongoing project from Norwegian company EDInsights, is using Earth Observation data and satellite L-band radar to measure snow storage across hydropower basins.

Elsewhere, Italian startup WaterJade combines precipitation and snow cover data with machine learning to create digital twins of catchment areas. Utility companies, including A2A and Edison, are using these models to reduce uncertainty around spring melt and flood risk.

WaterJade’s CEO Matteo Dall’Amico comments: “Our system allows us to track the water cycle at the basin level…[including] snow in the mountains, surface runoff on watercourses and deep infiltration into the aquifer.

“The forecasts are generally twice as accurate with respect to climatology, and hydropower operators can use the predictions to optimise energy trading and reservoir management.”

While digital tools are improving foresight, physical equipment remains essential to turning insight into action.

Ice management on the ground

Another primary winter pain point is ice, with much of the equipment deployed during winter focused on controlling or breaking up surface ice before it becomes a problem.

One such solution is an ice boom, which is a floating barrier deployed across rivers or lake outlets to manage ice movement. According to Sveinsson, these tools help accelerate the formation of a stable ice cover and reduce local frazil ice production.

In Canada, icebreaking has been part of hydropower operations for years.

Manitoba Hydro’s Jenpeg Generating Station on the Nelson River uses a purpose-built ice boom to form and retain an ice cover upstream of the facility. Meanwhile, Ontario Power Generation, which operates the Sir Adam Beck I and II stations on the Niagara River, deploys icebreaking vessels during the winter. Its Niagara Queen II, an 85-tonne icebreaker that has been in service since 1992, logs between 300 and 400 hours of service in winter, cutting through ice as thick as six feet before it can restrict flow or damage infrastructure.

While larger operations are typically deep enough to allow water flow to remain relatively unaffected, smaller and run-of-river plants are more vulnerable.

In these systems, ice management tends to be proactive rather than reactive. Operators may raise water levels to break up forming ice or manage water level fluctuations in reservoirs with thick ice cover to minimise the risk of damage to shoreline infrastructure or reservoir banks.

“Operators temporarily divert or flush flow into an empty waterway to help carry ice past intake areas instead of letting it accumulate and potentially freeze to the bottom,” Sveinsson explains.

Heating elements are also incorporated into the infrastructure itself to prevent frost buildup and flow restriction, such as on trash racks (metal structures designed to catch large debris) and gates.

Sveinsson adds: “Reliable and uninterrupted gate operations are critical to the operation of power plants. For this reason, equipment is often installed to heat the gates, seals and frames to ensure they remain ready for use and can be operated even during severe frost conditions.”

Taken together, these physical interventions mean hydropower facilities are well prepared to mitigate many of the negative impacts of freeze–thaw cycles, with their effectiveness amplified by improved forecasting and monitoring tools.

“With increased monitoring and longer lead inflow, forecasting changes can be anticipated and production planning optimised,” Sveinsson notes.

Future of hydropower in the winter

The convergence of digital forecasting tools and physical ice-management systems is proving integral to helping hydropower operators maintain productivity in the face of increasingly extreme winter conditions. The challenge is no longer simply to withstand extreme cold, but to anticipate how shifting snowmelt and freeze-thaw cycles affect water availability weeks or months in advance.

With satellite-based monitoring tools giving operators earlier visibility into cold weather risks, and long-standing equipment providing the means to act on that intelligence, sites are moving from reactive winter management to proactive planning.

Looking ahead, climate resilience is also expected to become an increasingly important consideration for operators. As Sveinsson posits, future improvements involve looking at hydrology as a dynamic rather than stationary force, as well as using climate data and modelling to track changes and increase resilience.

“In general, hydropower is built to withstand extreme winter conditions,” he says. “What is most important is to incorporate industry good practices to reduce vulnerability to climate change and make hydropower facilities more climate resilient.”

Scientific and regulatory alignment is a must

The growing complexity of modalities can place greater demands on a biopharma manufacturer’s capabilities to meet rising scientific and regulatory expectations. “A key challenge is adapting existing GMP-compliant operations with new technologies, which takes time and requires significant regulatory precision,” said Møller.

“Regulators have made a lot of progress, but of course, it’s difficult for them to advance at the same speed as science,” said Cameau. Cross-industry collaboration and a shared understanding of legal and scientific developments are vital, especially as more companies are developing therapies. “A more collaborative approach would ensure that the specificities of these new drugs are understood, and the authorities can make informed choices when developing them,” Cameau added.

In June 2025, the FDA removed Risk Evaluation and Mitigation Strategies (REMS) requirements for autologous CAR-Ts. Lifting this requirement is thought to expand the number of treatment centres qualified to administer them, and patients will no longer need to remain near hospitals for weeks after infusion. “Together, these scientific and regulatory advancements are unlocking a surge in demand for commercially accessible CAR-T therapies,” Gerlinghaus added.