AX CLEANER®

Air Cooled Heat Exchanger’s performances are falling down when their fins are fouled. How to clean them easily? That’s the question answered by our AX CLEANER®. Patented after 3 years of Research and Development, it is the most effective and most versatile existing cleaning solution.

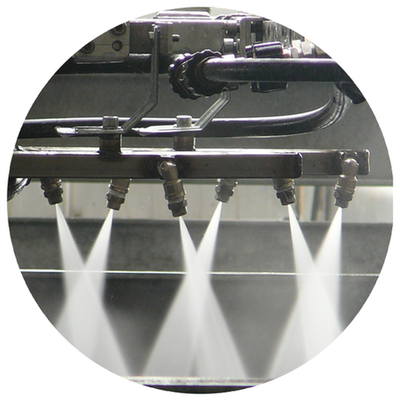

cleaning head

100% made of stainless steel, the cleaning head is sliding along rails in two directions, to cover the whole surface of the Heat Exchanger. The 16 conical flat shape nozzles fit any fin tube technology (aluminum flat tube, multi row…)

hose pusher

Installed on heat exchanger deck, this device has two functions: in pushing and pulling the hose, the pusher is driving the vertical motion of the cleaning head. Its hydraulic motor is using the same high pressure water as the cleaning head, so no electricity is required on the deck.

The hose pusher also comes with a spooling device, which stores the high pressure hose and makes the cleaning operation easier.

HIGH PRESSURE

PUMP UNIT

The pump supplies high pressure water to the cleaning head and the hydraulic motor of the hose pusher. Thanks to the frequency converter which controls the 22 kW electrical engine, the flow rate can be adjusted from 0 to 120 liter per minute, and the pressure from 0 to 130 bar. The pump is installed on the floor, bellow the heat exchanger, and is driven from heat exchanger deck by a radio remote control.

main components

OUR AX CLEANER®

FITS WITH ANY DRY

COOLING SYSTEM

Cleaning Solutions

FOGGING MODULAR SOLUTIONS

Our mission: find all the ways to improve air cooled heat exchanger efficiency. Following this vision, we developed a fogging solution, based on stackable modules, comprising up to 36 nozzles. The 0.4 mm diameter nozzles are spraying 10 microns water droplets, which evaporate when in contact with the air. During this state transition from liquid to vapor, an adiabatic reaction is absorbing calories and decreasing the air temperature.

Each module can inject up to 5.4 LPM at 70 bar. The quantity of modules per heat exchanger depends on total flow rate necessary to attain the performances required.

For example, for an ACC, 100 modules can be installed, spraying, 540 LPM and decreasing the airflow temperature up to 6°C, depending on weather conditions (temperature and relative humidity).

services

As a cleaning expert, AX SYSTEM is also dispensing onsite training, setup or commissioning. We also offer cleaning services.

OTHER PRODUCTS

As a high pressure expert, AX SYSTEM also designs and manufactures on demand solutions for demanding environments, like ATEX ultra high pressure pump, or

press-filter cleaning robots.

visit or contact us

Based in northern France with 10 years experience, AX SYSTEM manufactures high pressure cleaning solutions.

Our AX CLEANER® has been installed all over the world with any type of heat exchanger : A-frame and V-frame ACC, hexacool, ACC with louvers, flat heat exchanger, single and multi-row.

The company is motivated by a strong culture of innovation. 10% of our turnover is dedicated to Research & Development.

Our engineering department is composed of high experience technicians and engineers, who are experts in thermodynamics, mechanic of solids and mechanic of fluids.

AX System

allée des prêles

P.A. de la verte rue

59270 Bailleul - FRANCE

Tel : +33 (0) 3 28 43 58 40

contact@ax-system.com